There is no doubt about the fact that modern, cutting-edge technology ensures that industrial products like gates, barriers, and railings contribute to a safe work environment. However, it is the teeth provided under law, via 29 CFR 1910, the set of safety rules that applies to workplaces that ensure that workplace safety is given absolutely top priority in the industrial environment.

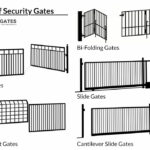

Take the case of industrial safety gates, for instance. These are of different types, with each of them serving a different and distinct function. For instance, safety swing gates, mezzanine gates, rooftop barrier gate, and temporary railings all have different and separate uses. Common to all of them is the fact that these would all have been manufactured according to benchmarks that conform to 29 CFR 1910.

29 CFR 1910 is enforced at workplaces by way of regulations, with citations being handed out for any compliance failures in the workplace. Safety is accorded the highest priority for everyone who has a stake in industrial and warehouse environments. Something like fall protection, for example, has come a long way since the days of the past when a rudimentary safety belt sold for no more than $50. Today, it has been replaced with a full-body harness that encompasses a retractable shock-absorbing lanyard mechanism that costs as much as $300.

That fall protection needs to be accorded all the importance that it can possibly receive is quite clear from the fact that citations issued on its account have been quite high historically. It is mandated that fall protection has to be provided at elevations of 4 feet and above in the case of general industry workplaces, five feet and above in the case of shipyards, six feet and above in the case of the construction industry, and so on.

It is the ability to be innovative that is making manufacturers across segments strive to conform to the benchmarks set by 29 CFR 1910. In the years ahead, mass customization of bespoke products is one trend to watch for. Companies who are doing this take advantage of innovative software that includes a 3D virtualized tool that can help one design complex products with multiple configurations.

This helps them ensure that their products are out of the top drawer and the least likely to fall foul of regulation like 29 CFR 1910. For instance, it is not acceptable under 29 CFR 1910 for ladders to openings to use chains for protection instead of gates. Equipment like overhead cranes cannot have chains instead of gates, as these can be a safety hazard.

There is no ambiguity whatsoever in the benchmarks stipulated under 29 CFR 1910 in matters concerning industrial safety. For instance, even if there are 4 steps in a stairway, railings or handrails are required to be in place. If a stairway is less than 44 inches wide and enclosed on either side, one handrail would do. In the event that one side is open, a railing on the open side will do. In case both sides are open, standard railings should be put in place on both sides.

Wherever the stairway is between 44 and 88 inches in width, a handrail is to be installed on each enclosed side and a standard railing on each of the open sides. Any stairway which is more than 88 inches wide, is also required to have a handrail on each enclosed side and an intermediate railing halfway across its width.

While industrial growth augurs well for the economy, when it comes to the safety of workers, not the slightest compromise can be brooked. This is something that manufacturers of industrial products are very sensitive to and make constant efforts to update their safety features from time to time.

Advances in technology have made it possible for manufacturers to design ever safer products that also help enhance worker productivity. It helps that they have a benchmark like the 29 CFR 1910 to guide them. The leading manufacturers of gates, barriers and railings are a fine example of how modern, cutting-edge technology can be harnessed to improve products both in terms of their safety and efficiency.

As we move into the digital era, it has become possible to refine product designing to an extraordinary level of accuracy, making them even safer and more efficient. Going forward, one can expect even better products both in terms of safety and efficacy, resulting in ever-improved output and fewer accidents and mishaps. A lot of credit for this should go to the stringent provisions of 29 CFR 1910, which have ensured that the focus on safety has always received top priority when it comes to such industrial products being conceptualized, designed and manufactured.